13 Aug 2018

Oliver Tilling covers the aspects of calf rearing to plan for to maximise success for your clients, focusing on calving, colostrum, feeding, housing and disease.

Figure 1. A complete calving toolkit: calving aid, nylon obstetrical straps, a head rope, plenty of obstetrical lubrication, long-sleeved disposable gloves, clean buckets, antiseptic and a mobile.

On average, 8.1% of calves are dead within 48 hours – so, in other words, a stillbirth. Of this figure, 78.6% are born dead, although most are alive when calving starts. A total of 21.4% are born alive, but die within 48 hours1.

Birth, therefore, represents the period when most calves die on a farm. For calves that survive, but suffer dystocia, there are increased odds for failure of passive transfer, and morbidity and mortality later in life.

The cow should move from the close-up dry cow area into the calving pen as close to calving as possible, but no later than 24 hours before calving. If she spends too long in the calving pen, it can get too dirty². The calving area should be clean, dry, with good grip, and quiet.

Sand or rubber matting covered in deep straw is ideal. Good lighting to facilitate observation should be in place, along with facilities to provide food and water, and the calving pen should be isolated from other areas of the dairy to prevent the cow from becoming distracted or stressed by commotion from other farm tasks2. The door needs to be large enough to carry a cow in, in a bucket on a front-end loader, and also to remove the unfortunate fatalities that may occur3.

Width of an individual calving pen must be at least 1.5 times the cow’s length; length should be at least twice the cow’s length. This will allow the cow to lie down comfortably and deliver a calf. If assistance is required, facilities must allow for at least one cow length behind the cow4. Calving pens must be thoroughly cleaned between uses. One per 25 cows is required if calving takes place all year round2.

Group calving pens require fewer workers for monitoring, but cows often spend longer in them, leading to a greater build-up of pathogens. Around 15m² space per cow is required, and 8kg to 12kg of straw per cow per day.

Less than 10 cows should be housed to prevent overcrowding, lack of feed space, reduced dry matter intake and reduced subsequent reproductive efficiency2. Sick or lame cows must never be housed in the same pen as calving cows – they represent a huge risk to the newborn calf.

The final thing to ensure before a calving is that all necessary equipment is available, clean/sterilised, and in good working order (Figure 1).

A standard operating procedure for calving cows is essential to ensure everyone who could be involved knows what to do. This must include accurately recording cow and calf numbers each time. This should form part of a herd health plan and be reviewed annually, with training for new members of staff.

Calves that receive adequate colostrum have a reduced risk for pre-weaning morbidity and mortality, plus:

Effective colostrum management is the cornerstone of a good calf-rearing programme. The focus must be on five key areas:

Good-quality colostrum has high levels of immunoglobulins in it. Their concentration is highest immediately after calving, and decreases by 3.7% during each subsequent hour post-calving. Time of first milking is, therefore, the most crucial factor regarding colostrum quality that farmers can influence6.

The cow should be milked out completely as soon as she calves. She should produce up to eight litres of colostrum (a heifer up to six litres) and it should all end up in the calf. Waiting until the next milking to harvest colostrum is unacceptable.

Other factors under the farmer’s control that affect colostrum quality include:

The most important factor determining successful passive transfer is the quantity of colostrum ingested or administered to the calf. Dairy calves left with their mother will not ingest an adequate volume of the relatively dilute dairy cow colostrum to meet their immunoglobulin requirements7. The concentration of immunoglobulins in the colostrum being fed is unknown, so it is recommended calves are fed 10% to 12% of their bodyweight of colostrum at first feeding5, namely approximately four litres.

Calves left with their mother have a 2.4 times greater risk of FPT in comparison with hand feeding8. Removing the calf as soon as possible from the dam and feeding four litres of mother’s colostrum with either a nipple bottle or oesophageal tube (Figure 4) means the farmer can walk away confident the calf has received an appropriate quantity of colostrum.

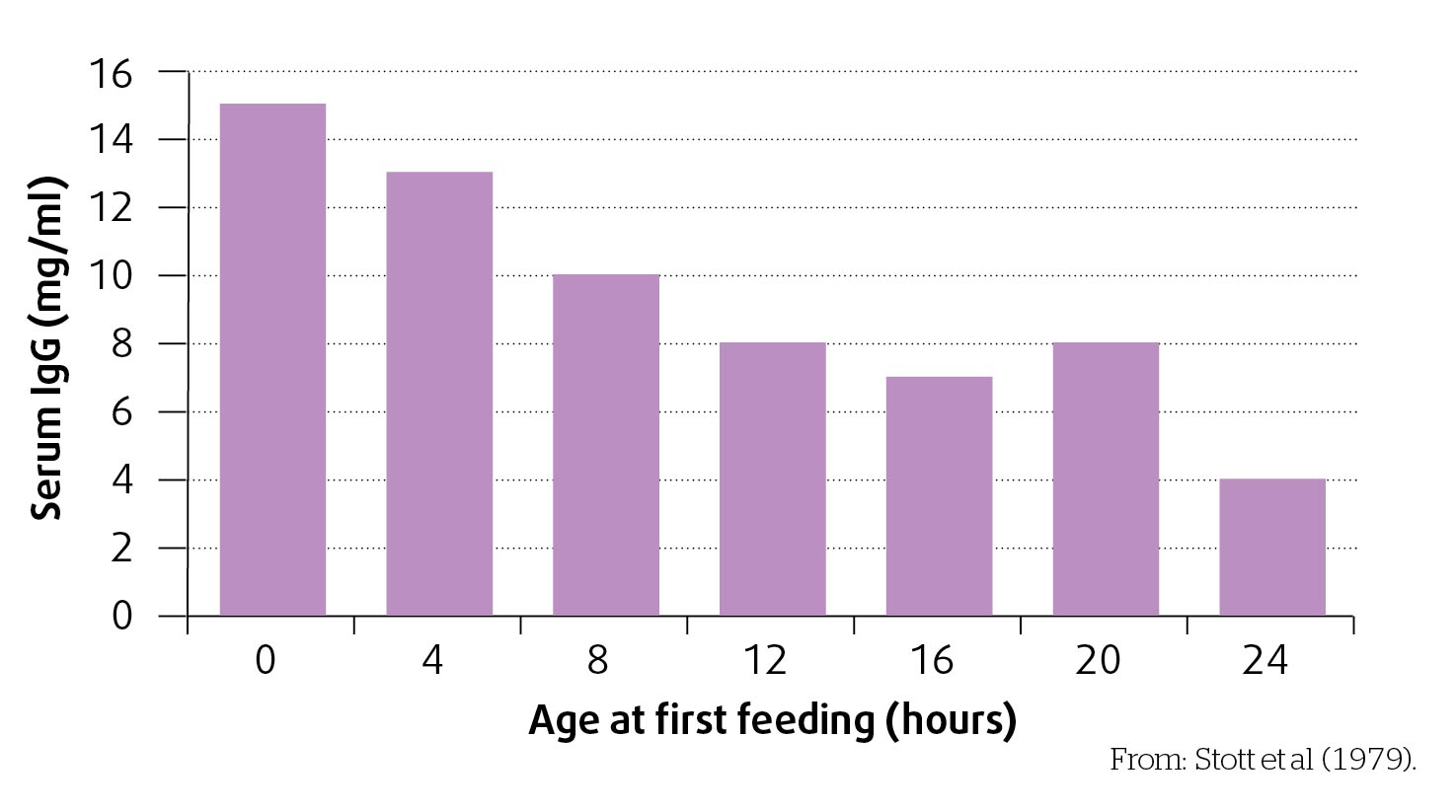

Quality of colostrum is affected by how soon it is harvested. Absorption by the calf is affected by how soon it is fed. In a process referred to as “closure,” the efficiency of immunoglobulin absorption through the gut lining of the calf decreases with time from birth to be completely closed at approximately 24 hours5.

Despite the length of time to gut closure, immunoglobulin transfer across the gut is optimal in the first four hours after calving, with a progressive decline after six hours. Calves fed colostrum more than four hours after birth are 2.7 times more likely to have FPT than those fed within four hours of birth8. This is because fewer immunoglobulins are able to get through. Figure 5 shows how calves fed later have lower immunoglobulin levels9.

Despite the window being closed after 24 hours, continued feeding of colostrum over the next several days is beneficial by providing local immunity in the gut. This helps to prevent/reduce the severity of bacterial and viral infections that cause diarrhoea in the first few days of life10.

Colostrum is an important source of nutrients and immunoglobulins, but also represents one of the earliest potential exposures of calves to infections5.

Bacteria in colostrum may bind free immunoglobulins in the gut or block uptake and transport of immunoglobulins into the cells lining the gut, thus reducing efficiency of absorption11.

In addition, prior to “closure” the gut is non-selective in its absorption, and so direct uptake of bacteria may lead to septicaemia or diarrhoea.

Colostrum total bacterial count (TBC) should not exceed 100,000 colony forming units (cfu)/ml and faecal coliforms should be below 10,000 cfu/ml 6. A nationwide evaluation of quality and composition of colostrum on dairy farms in the US found almost 43% of colostrum samples collected had TBC greater than 100,000 cfu/ml, and 16.9% of the samples had greater than 1 million cfu/ml 11.

Keeping colostrum squeaky clean involves preventing colostral bacterial contamination, plus minimising bacterial growth in stored colostrum. The cow should calve in a clean straw yard. The udder should be hygienically prepared before collection of colostrum (Figure 6).

Clean technique and milking equipment, which is clean and in good working order, are necessary to minimise bacterial contamination of colostrum12. TBCs are low or nil in colostrum stripped directly from the udder. This emphasises the need to minimise contamination by milking into a clean, sanitised bucket, keeping collected colostrum covered, and handling colostrum using clean, sanitised storage or feeding equipment5.

Colostrum provides a perfect medium for bacterial growth13. Unless fed right away, it should be frozen or refrigerated within one hour after collection5. A store of frozen colostrum is very important preparation for calf rearing. Only colostrum of good quality measured by a colostrometer or Brix refractometer should be frozen.

It can be stored for up to a year at -18°C to -20°C. Freezer bags that freeze flat, and so defrost quicker than milk cartons, are best (Figure 7). Cow ID and date of storage should be written on the bag in permanent marker to allow older stored colostrum to be used first, but also so the colostrum can be discarded if a cow is later identified as having Johne’s disease.

Thawing can be done in a clean water bath/bucket no greater than 60°C (140°F) to avoid destroying immunoglobulins. Microwaves should be avoided. Before feeding to the calf, temperature of the colostrum must be checked – the target is a calf body temperature of 38.5°C.

Colostrum management practices must be monitored. Serum total protein by refractometer is the most reliable test for herd screening7. It is a simple, rapid and inexpensive tool. All farm veterinary practices should have the necessary equipment for this. A serum total protein concentration of 5.2g/dL is equivalent to an IgG concentration of 1,000mg/dL.

In a healthy, adequately hydrated calf a serum total protein of 5.2g/dL or greater is, therefore, associated with adequate passive transfer.

Regular monitoring of colostrum management by blood sampling calves enables longer-term patterns to be built up. A target of 85% or more of all calves sampled having a result of 5.2g/dL or greater is readily achievable. The odds of FPT are nearly 14 times higher on farms that do not routinely monitor total proteins to assess passive transfer compared to those that do8.

Calves like a boring life. They want the same feed, in the same way, at the same time, every day. Variation increases stress for the calf, reduces growth rates and increases risk of disease. Farms need a clear feeding programme: a plan of activities and actions that allow consistency in calf feeding.

The feeding programme must set out the timing of feeding and the daily amount of milk to be fed from birth to weaning. It sets out the types and amounts of each feed, and the number and timings of feeds per day14. It should include:

Anyone involved in the calf feeding must be aware of the routine. Clear lines of communication should be in place between staff, such as a diary, a notice board in the calf shed and calling, texting or emailing to pass on relevant information. The routine should also include regular assessment of the success of the feeding programme in conjunction with the vet, which will include monitoring performance and record keeping.

Seven key areas must be kept in mind to ensure housing is appropriate for calf rearing:

Moisture is ever-present in animal housing (Table 1). Pathogens that cause scour and pneumonia find it hard to survive in dry conditions, but thrive in moist environments. The aim must be to keep moisture out, and what calves produce under control (Table 2).

| Table 1. The effects of too much moisture17 | |||

|---|---|---|---|

| Factor | Condition | Contribution | Signs |

| Moisture | Too much | • Supports microbial activity • Promotes bacterial growth (some species) • Absorbs energy • Acts as a transport medium • Increases slippery floors – stress |

• Dirty water lying • Dirty cattle • Damp floors in areas that could be dry • Water ingress • Leaking drinkers • Condensation • Staining of underside of roof • Animal health… |

| Table 2. Options for improved moisture management and control17 | |

|---|---|

| Competent drainage | • 1 in 20 slopes under straw. 1 in 10 under any feeding or drinking areas • Channels in floors to intercept excess liquors • Drainage within pen, between pens, within building and outside |

| Competent ventilation | • Heat and moisture are continually produced and must be continually removed, along with bacteria, viruses and gases |

| Dry bedding | • To maintain thermal comfort and to absorb excess moisture at animal level • Good straw and manure management |

| Sympathetic building materials | • Cold surfaces promote condensation, keeping moisture in the building. Considerate concrete and use of tin |

| No additional moisture | • Moisture can be prevented from entering a cattle building by attention to downpipes and gutters, good building maintenance, and keeping groundwater away by sensible drainage |

Moist environments are also cold environments. A calf lying on wet straw starts diverting energy from growth to maintaining body temperature at 10°C compared to a calf lying on dry straw, which starts at 8°C15. Prolonged periods of exposure to moist conditions can also lead to physiological stress, with the eventual outcome being a calf that is unable to maintain an adequate immune system. These calves are more prone to infections15.

Bedding and drainage are essential to minimise accumulation of moisture. Bedding must keep calves clean and dry, and be comfortable to lie on – comfortable calves lie down for more than 19 hours a day.

Movement pressures in a building should be addressed. Excess water will accumulate:

How much is too much moisture? Answer: When you can see it.

These areas need an additional slope of 1 in 10 and channels to specifically gather and remove excess liquid from the animals’ environment. Calves spend up to 80% of their time lying down, so a 1 in 20 gradient below bedding is needed, plus:

Liquids moving from a pen should not move into an area exposed to foot traffic of workers. The slope of a pen can be to the front or rear, with drainage channels located accordingly and designed to then carry liquids to collection points outside16.

Fresh air is free and kills bacteria and viruses. Having 100% fresh air kills bacteria 10 times quicker than 50% fresh air17. The way to ensure a building has adequate fresh air is to have a good ventilation rate.

Ventilation rate is the amount of air replaced within a building within a given time. The minimum change required within a building is 10 times each hour, increasing in the summer to 60 air changes per hour18. Natural ventilation works on the principles of the stack effect.

It is important a building is designed to allow the ventilation to18:

Design requirements are not easy to achieve, as most buildings have no moving parts, except the doors, the weather is changeable and can come from all directions, and the internal conditions – including numbers and weight of animals – constantly change. However, a few basic rules can be applied to assess whether the ventilation of a building is providing a healthy environment for the cattle living inside it15:

The outlet area needs to be 0.04m2 per calf.

In addition to inlet and outlet design, a number of other points to be considered in the design of a successful natural ventilation system are18:

Almost all calf sheds would benefit from having a supplemental positive pressure ventilation tube, due to the inability of young calves to drive the stack effect (Figure 11). An evenly distributed outlet is still required in the roof, to allow the air pushed in to escape.

If designed properly, the tube systems will deliver fresh air without a draught into microenvironments within the calf building. The air introduced through the tubes is distributed around the building and then exits passively through the outlets16.

Air speed in the part of the building where cattle stay should not exceed 0.2m/s to 0.5m/s. If this happens, the ambient air temperature may result in an increased cooling of the surface temperature of the animal, namely a draught19.

Increased air speed at animal height increases the risk of immune suppression, and severely increases the negative impact of low temperatures on youngstock15. Conversely, low air speeds into buildings are associated with insufficient delivery of fresh air (Table 3).

| Table 3. The effects of air speed17 | ||

|---|---|---|

| Air speed | Contribution | Signs |

| Too much | Associated with excessive energy loss | • Animals avoiding certain areas • Huddling • Hairy coat • High intake/low production rates • Animal health… |

| Too little | Associated with lack of fresh air | • Animals avoiding certain areas • Smell • Animal health… |

Air speed is the most important factor in terms of immediate impact on youngstock. A draught will reduce the animal’s energy the quickest and so do most damage, because it moves the parameters fastest.

Table 4 shows even a small increase in air speed at animal height increases the lower critical temperature (LCT) significantly and is even more of a thermal stress than lying on a wet bed. Higher air speeds above 2m/s, such as in a draught, will increase the negative effect.

| Table 4. The effect of air speed and calf weight on the lower critical temperature (LCT) of a calf15 | ||

|---|---|---|

| Calf weight (kg) | LCT (°C) at two different air speeds | |

| 0.2m/s | 2.0m/s | |

| 35 | +9 | +17 |

| 50 | 0 | +9 |

| 100 | -14 | -1 |

A calf’s LCT is the temperature below which it has to divert additional energy towards keeping warm. At this point, less of the feed consumed is available for growth. This reduces daily live weight gain, because feed efficiency is reduced. Prolonged exposure to ambient temperatures below LCT becomes a physiological stress, so an animal is more likely to succumb to disease.

Housing does not generally need to provide additional heating beyond the needs of the calf’s own body mechanisms; it simply needs to maintain the thermo-neutral zone for them. This is done by managing moisture, fresh air, air speed, bedding and drainage. For this reason, and depending on how a house is managed, the temperature the animal feels is often different to the actual air temperature.

For calves, however, the requirement for additional heat in the calf house varies according to the calf/calves, weather and quality of calf house environment. The LCT of a calf up to three weeks of age is 15°C; below this it needs to expend energy to keep warm. One way to help the calf warm is with a jacket (Figure 12).

If designed properly, the outer shell of the calf jacket will prevent outside moisture from penetrating the calf’s hair coat, keeping it dry. The calf jacket insulation layer should be made of moisture-wicking material, channelling moisture away from the calf’s body and preventing sweat from building up and getting the calf’s coat wet.

Calf heaters or heat lamps can also provide additional heat in the calf house. Most frequently used for sick calves, they can also be used to raise the temperature in the pens of healthy calves.

If temperatures lead to increases above the upper critical temperature (UCT), appetite is reduced and water requirements increase. This, too, leads to reduced daily live weight gain and increased risk of disease. When considering heat stress, not only is temperature important, but also relative humidity.

Used as a reference for heat stress in dairy cows, the Temperature-Humidity Index (Table 5) is still relevant for dairy calves and heifers.

| Table 1. Temperature-Humidity Index for dairy cattle | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Relative humidity % | |||||||||

| 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | |

| 22°C | 66 | 66 | 67 | 68 | 69 | 69 | 70 | 71 | 72 |

| 24°C | 68 | 69 | 70 | 70 | 71 | 72 | 73 | 74 | 75 |

| 26°C | 70 | 71 | 72 | 73 | 74 | 75 | 77 | 78 | 79 |

| 28°C | 72 | 73 | 74 | 76 | 77 | 78 | 80 | 81 | 82 |

| 30°C | 74 | 75 | 77 | 78 | 80 | 81 | 83 | 84 | 86 |

| 32°C | 76 | 77 | 79 | 81 | 83 | 84 | 86 | 88 | 90 |

| 34°C | 78 | 80 | 82 | 84 | 85 | 87 | 89 | 91 | 93 |

| 36°C | 80 | 82 | 84 | 86 | 88 | 90 | 93 | 95 | 97 |

| 38°C | 82 | 84 | 86 | 89 | 91 | 93 | 96 | 98 | 100 |

| 40°C | 84 | 86 | 89 | 91 | 94 | 96 | 99 | 101 | 104 |

| ■ No heat stress | ■ Severe heat stress | ||||||||

| ■ Moderate heat stress | ■ Dead cows | ||||||||

| Adapted from Frank Wiersma, University of Arizona, 1990. | |||||||||

Lighting must be adequate in a building to allow cattle to be inspected at any time. If natural light is insufficient to allow this, artificial lighting must be provided. However, cattle need an appropriate period of rest from artificial lighting18.

Cattle are daytime creatures. Up to calving, either natural light – with 10% of the roof as translucent sheeting – or artificial light at 100-200 lux at animal level to aid observation is appropriate14.

Plentiful light doesn’t just make things easier for working with calves; it also has significant effects on the calves.

As the hours of daylight decrease, the deposition of body fat increases. Insufficient light is interpreted by the calf as winter conditions. In response, the animals start to lay down body fat. Increasing hours of daylight to 16 using artificial light promotes efficient use of nutrition. Less fat will be laid down in favour of building more muscle protein, so increasing growth rates.

Fresh feed delivery is the primary motivator for cattle to come to eat. With feeding of concentrates to groups of young calves, all members of a group should have space to eat at the same time to ensure that the smallest, most timid individuals have similar access to feed as larger or more high-ranking individuals in the group. The feeding area must be of an appropriate throat and table height for the size of calves using it (Table 6).

Adequate trough space or water bowls must be provided to allow at least 10% of a group to drink at anytime18. Ensure water troughs are not too tall. Small calves may have difficulty reaching water if the trough is placed on the feed table20. It is best to locate water troughs or bowls towards the front of a pen over concreted or free-draining areas.

Table 6 shows feed and water space requirements for calves and heifers by weight. In practice, it is often difficult to achieve specific requirements due to animals growing and/or a mixture of age groups. If this is the case, allocations should be based on the average weight of the animals in the group, but monitored very closely to ensure all individuals have good access to feed and water.

| Table 6. Feed and water space requirements for calves and heifers by weight21 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Bodyweight (kg) | <60 | 60 | 100 | 150 | 200 | 300 | 400 | 500 |

| Approximate age – Holstein (months) | 1 | 1.5 | 3 | 5 | 7 | 11.5 | 15.5 | 20 |

| Feeding space, width per head (cm) | 30 | 30 | 36 | 41 | 51 | 56 | 61 | 66 |

| Feed manger floor height above the litter alley floor (cm) | 10 | |||||||

| Throat height above the litter alley floor (cm) | 33 | 33 | 36 | 37 | 38 | 42 | 46 | 50 |

| Neck rail height above litter alley floor (cm) with slant bar feed barrier | 76 | 86 | 97 | 104 | 112 | 122 | 127 | |

| Neck rail height above litter alley floor (cm) with post-and-rail feed barrier | 71 | 76 | 81 | 97 | 112 | 117 | ||

| Water trough perimeter per head (cm) | 5 | 6 | 8 | 9 | ||||

| Maximum water height (cm) | – | 74 | 79 | 84 | 86 | |||

Cleaning is very important, requiring the right materials and the right amount of time to do the job. Poor hygiene for any cattle is unacceptable.

The most important part of a good hygiene policy, especially in modern production systems, is time − not only to carry out the work, but also to allow floors, pens, fittings and utensils to dry after wetting. A short dry period helps kill bacteria and viruses that survive the active cleaning process, and is a vital part of biosecurity15 (Figure 13).

Disease is an unfortunate reality when rearing calves. However, because disease is an almost inevitable fact of calf rearing, preparation is essential. A large part of this preparation will focus on the other aspects discussed. It is further important to work with clients on how to recognise disease, what caused it, how to treat it and how to prevent it happening in future.

Effective treatment protocols must be established, but the main focus of veterinary involvement must be on control and prevention. The two main diseases we are confronted with in calf rearing are diarrhoea and pneumonia.

Irrespective of the causal agent, the route of infection for infectious diarrhoea is the same – ingestion or inhalation of the organism from an environment that is heavily contaminated by faeces.

Hygiene and cleanliness are paramount, and along with good colostrum are the key to prevention and control of diarrhoea.

Good hygiene must start from the moment the calf is born, as many infections are picked up from the calving area. Hygiene and cleanliness must be maintained throughout the calf-rearing period, with specific care being taken to clean and disinfect feeding equipment between feeds and to thoroughly clean the environment on regular occasions and between batches of calves.

Scour is 1.9 times as likely when calves are reared on wet bedding, and 0.6 times as likely when there is disinfection between groups21.

Vaccination is available for many infectious scour organisms, including Rotavirus, Coronavirus, E coli, Salmonella dublin and Salmonella typhimurium. Nutritional scour can be prevented by having a clear and consistent protocol for feed preparation.

Vaccination has an important role to play in the prevention of calf pneumonia, but good diagnostics are required in the first place so you know what the causative agents are. This prevents incorrect treatment and/or vaccines being used with poor outcomes.

Vaccines are now available that provide effective control against the most common bacterial, viral and parasitic causes of calf pneumonia. Programmes should be designed to take into account the circumstances on individual farms and should be based around knowledge of the risk factors and the circulating pathogens22. Basic management issues must be addressed first to ensure that specific pneumonia control strategies have the best possible chance of success.

It could be argued all these other changes should be made first before vaccination is employed. In practice, however, making changes to existing buildings, reducing stocking rates and/or changing feeding patterns is not always possible straight away. As much as possible should be done here first. However, the calf sits on one end of a scale, and if vaccination, combined with some management changes, helps to balance the scale – and stop pneumonia – it can and should be used.