8 Aug 2017

Mastitis control in robotic milking systems

Peter Edmondson looks at various factors to take into consideration when adopting this technology in the dairy environment.

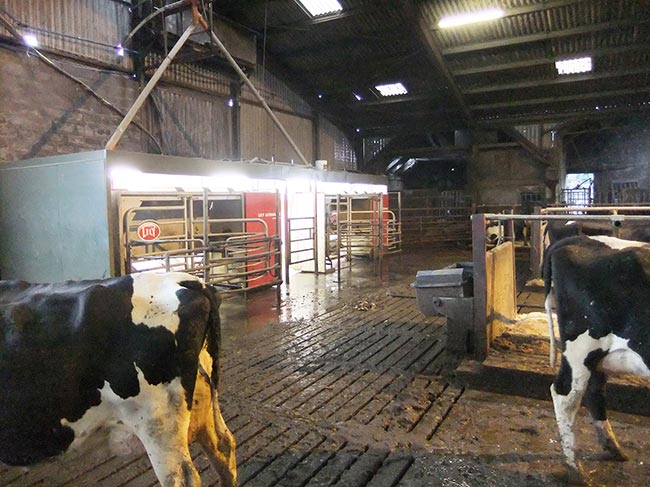

Plenty of space and a clean environment minimises the risk of clinical mastitis.

Love it or hate it, technology is taking over our lives. Great excitement took hold when the first mobile phone arrived and allowed us to make telephone calls, then came text messaging. Now, everyone takes smartphones for granted and they have more technology than the computers used to send the first man to the moon.

So much has changed, and we see this on farms. Dairies are getting bigger and getting staff can be challenging, which could become even harder following Brexit. This is one of the attractions of milking robots – also known as voluntary milking systems – which can improve the farmer’s quality of life, as well as help with labour issues.

Around 80,000 robots are working worldwide and the numbers are increasing exponentially. Large herds are putting in more numbers at a time, rather than the two or three robotic units we are used to.

We are also seeing robotic rotary parlours, which require a supervisor rather than a whole milking team. We can expect more technological advances and changes as robotic systems continue to develop.

In the past decade, we have learned more about robots and their technology has improved greatly. It is important vets understand robots and how they function in relation to mastitis and milk quality.

Quality of life

With robotic milking systems, you are buying quality of life. You are no longer tied to having to milk cows at set times, two or three times a day. The cow decides when and how frequently she is milked each day. It is animal welfare friendly and cows adapt extremely well from being milked in conventional parlours to robotic systems.

You are also getting consistency in the milking routine. We are all well aware of the problems in getting people to work on farms. Farmers want to retain their milkers because they know good milkers are like gold dust.

The milking routine is constant in robotic units. No operator error or variation in how the cow will be prepped or milked exists and we know cows like routine and consistency.

Hygiene

It is essential cows are kept in conditions that ensure the teats and udders remain clean, so the robotic unit is able to clean teats effectively. This means having a well-designed housing system where cows lie down on clean beds.

Most robotic systems have cows housed all year around. You need to make sure the stocking density is correct and should have, at most, 95 cows per 100 cubicles, which must be well-bedded and comfortable. Wide passageways should also be apparent and regularly scraped.

Occasionally, robot cows are kept on straw yards, but are very difficult to manage as cows can lie anywhere. Some people have cows at pasture, but this can be challenging if the pasture conditions become dirty and cows are milked with filthy teats.

At present, units have a set routine, irrespective of how clean or dirty the teats are. It is likely future technology will be able to differentiate between clean and dirty teats, and adjust the preparation accordingly.

We know if we keep cows in clean conditions we minimise the risk of clinical mastitis due to environmental organisms, such as Escherichia coli and the coliforms. This also helps protect against high bacteria levels in milk and helps enhance milk quality through low Bactoscan counts.

Capacity

Robot capacity is decided by the volume of milk harvested each day, rather than the number of cows. Efficient robots will milk between 2,000 and 2,200 litres per day. The one thing everyone notices when you move to robotic milking is how quiet the cows become; their stress levels drop off, so this is good for overall health.

Some cows are very robot efficient; that is, they know how to play the system to maximum effect and come in when they know they will be milked. Feed is the key factor that encourages animals to come for milking. Teat condition improves as you are milking individual quarters, so risks from over milking reduce.

It is advisable udders should be singed every three or four months to avoid dirt getting trapped around the teat. Hairy udders make teat prep more difficult and can interfere with unit attachment if the lasers get confused with shavings or dirt trapped in hair.

Tails should be clipped regularly as this will avoid manure being splashed on to the back of the udder and rear teats.

Infection spread

Spread of contagious mastitis infections, such as Staphylococcus aureus, can occur in any milking system – even with post-milking teat disinfection or cluster flushing with a disinfectant solution.

Post-milking teat disinfection reduces the new infection rate by 50 per cent, if the entire surface of the teat is covered. Most robots spray post-dip through a fixed or moving spray nozzle and the outer parts of the teats are often missed, meaning an increase in spread of infection can occur.

Robots rinse the liners with water after each cow, which helps reduce the amount of residual milk, but does not sanitise. Robotic equipment manufacturers do not advise using a disinfectant rinse between each cow because they are concerned about chemical contamination of milk. Remember, the milking robot is a food factory.

It is important to remove cows with chronic subclinical mastitis before moving across to robotic milking. This reduces the level of infection, so the impact of any spread will be reduced. In general, cell counts tend to be slightly higher in robotic systems compared to conventional herds.

It is easy to pick up a cow with clinical mastitis in a parlour. With robots, you are totally reliant on technology. They detect mastitis in a variety of ways, including electrical conductivity and light emission through milk. Warning systems will always err on the side of caution and more warning messages will occur than true clinical cases. The farmer can then decide a problem exists and whether the cow needs to be checked.

When you speak to most farmers who milk using robots, they will tell you between five and eight warnings occur for every true case of clinical mastitis. This is something to be expected. Not all warning messages mean trouble. Watch out, as some people are convinced technology is always 100 per cent accurate and every warning message means something must be treated.

Administration

It is easy to administer treatments in the parlour, but with robots, you must find the cow and bring her somewhere to administer treatments safely for the cow and operator. All this takes time, so is labour-intensive.

Some setups have a separate crush; others treat in cubicles, which is not very safe or hygienic. Some treat cows in the robot, butthis can be dangerous as you end up bending down in an area full of metal where a high risk of getting injured can exist – especially if acow kicks.

Treatment frequency is a consideration and once daily is preferable to twice as it reduces stress on a cow and is less work for staff.

Idle time is when the robot is available for milking, but not used. The target is to have a minimum of 15 per cent idle time to maximise throughput and yield. If adequate idle time is allowed, cows will be milked more frequently as less queuing is apparent.

They will have lower cell counts and fewer cases of clinical mastitis. Think of a busy bar at a football match – so much queuing and barging happens it is difficult to get to the front to be served. You might give up trying to get a drink altogether; the same is true if you have low idle times.

One robot farm with a five per cent idle time dried off 3 out of 50 cows in the group. The following day, the volume of milk from the remaining 47 cows remained the same – that is, milk per cow increased due to increased visits, so robots were inefficient when overstocked. This shows the importance of idle time. Low idle times increase the risk of clinical mastitis. The quiet milking times are around 2am to 4am, when cows are “chilling out”. You should see robots empty at various times.

Idle time

Robots are expensive and every farmer is keen to maximise return on investment. However, robots cannot milk 24 hours a day as they have to be washed three times a day. The wash cycle length varies according to the manufacturer; some take 12 minutes, others take longer. A long period of cluster rinsing occurs after milking cows that have been treated to ensure no medicine residues enter the bulk tank. High levels of treatments requiring milk withdrawal reduce idle time.

Cow flow and environmental management is key to success. Some people try to squeeze robots into existing facilities without fully considering the true impact of cow flow and acceptance. For free access robots, where cows can walk straight into them whenever they want, you need a five-metre area around the robot. If you have two robots side by side, this needs to be seven metres.

You need to carefully consider if you can fit robots into existing facilities. There have been disaster cases where this has occurred, but also great successes when properly designed. Probably the best units are well-designed greenfield sites.

The importance of farmers visiting as many robotic farms before finalising plans for a new unit is to be encouraged. Designs can always be improved.

Work process changes

Robots change how people work. You save time from milking, but can spend more time with the computer and examining individual cows, so you do not necessarily reduce labour input; you just work differently.

Remember, with robots you have to fetch cows for treatment, carry out lots of checks as you don’t see cows in the parlour twice a day. You have to work with the computer to find out where potential problems lie.

You need high levels of stockmanshipand people who understand the robot’s computer. It changes the way you work andthe environment is very quiet and relaxed.You do not have to stick to a strict timetable and, if problems do arise, the robot will alert you by telephone.

To maximise production and hold a good lactation yield, you need to feed cows well to make robots perform to their best. A key performance indicator is for at least three milkings per day, by day 21 post-calving. Lactation yield for the rest of lactation will drop off more rapidly if this is not achieved.

Many early lactation animals – especially heifers – are milked between four and six times a day, and time their visits so they are not rejected. Robots will reject cows milked very recently, so it is best to have cows that are robot friendly and know when they go to the robot they will be milked.

You don’t want “time wasters” that just clog up the system trying to be milked very frequently, as they reduce idle time further.

Conclusion

Everyone agrees it costs more to milk via a robot; you are buying a lifestyle choice. However, people use the time they free up to improve management, so increase yield and productivity. As a result, these systems can be more profitable and enjoyable places to work.