10 Dec 2018

Peter Edmondson looks at minimising drug residue in milk, in which human error has been found to be a major cause of bulk tank failure.

Around 12,000 dairy farmers exist in the UK and around 90 bulk milk samples fail every month. The UK bulk tank failure rate is around 0.25% and has remained at that level for several years.

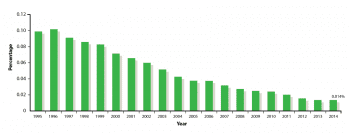

Compare this to the US and Denmark, which are 0.013% and 0.016% respectively, based on testing every sample. Figure 1 illustrates the percentage of bulk tank failures in the US, showing the number of failures has been falling year on year.

Most dairy companies only test bulk tank samples once a week and rely on the testing of individual tankers before milk is offloaded. Some milk buyers are starting to test every load for residues. When they move from weekly to daily testing, an increase is initially seen in the number of failures, but this quickly starts to drop down to below previous levels.

So, what is different between the US and the UK? The US regulatory authorities require training and risk analysis. Every year, US dairy farmers and their vets must work through a 10-point hazard analysis critical control point risk assessment as part of their dairy contract. This is certified, takes time, costs money and is highly successful and valued by farmers.

The Danes also have a formal training programme for farmers who must undergo a risk assessment and tighten up on weak areas. Something must change if we want to reduce the number of failures in the UK.

Human error causes failures – failure due to medicine problems are very uncommon. Surveys into the causes of failure have been limited; however, Macrae et al (2017) carried out a survey of bulk tank failures between 2015 and 2017. The farmers were asked to give their reasons for the failures. Table 1 lists their reasons and shows all failures were down to human error, except for three cases where farmers presumed antibiotic was excreted beyond the milk withdrawal period, which has been found with some products when cows get hypocalcaemia post-calving, which slows down the excretion of some dry cow antibiotics.

The risk of residue failure will be minimised if the following steps are taken.

It is essential all people involved in treatment or milking are trained so they understand their role in residue avoidance. Training should include part-time milkers and should be ongoing. It should include an understanding of the importance of producing milk free from residues, the implications of residue failures and key steps that should be taken to minimise contamination occurring. Treatment should follow the guidelines set out in the herd health plan as drawn up by the farm vet.

All treatments given to food-producing animals must be recorded. Vets who treat animals on farm must ensure they have either entered treatment details in the medicine book or left a note of all required information so the farmer can enter it.

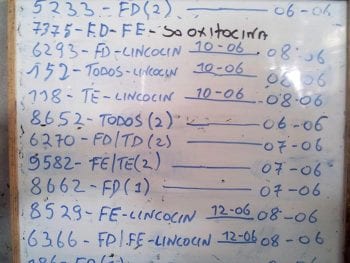

A noticeboard in the parlour is a good method of communication so all milkers can see which cows have been treated and on what date (Figure 2). This is in addition to recording information in to the medicine book or farm computer.

It is essential all treated cows are clearly identified so their milk can be discarded. It is advisable to mark the cow before any treatment is administered. Most dairy farmers identify treated cows using leg or tail tape, spraying of the udder, and entering treatment details in the milking parlour computer. Ideally, two forms of identification should be used.

Some farmers still don’t have any recognisable form of cow identification other than an official ear tag number. It is essential all cows have a clearly identifiable management number. Freeze brands on the hindquarters are an excellent form of identification as the milker can clearly identify each cow from the milking pit.

Larger herds have treatment groups that are milked last (Figure 3) and the very large herds have a separate parlour and housing. It is best practice to keep any cows whose milk must be discarded in a hospital group milked last to avoid accidental transfer to the bulk supply.

If this is not possible, treated cows should then be milked through a dump bucket or dump line. Many new parlours have dedicated dump lines; however, a milker might not realise a cow’s milk needs to be discarded and so human error can cause a failure by accidental transfer.

If cows are milked through a recorder jar, it is essential it is thoroughly rinsed out after milking as antibiotic residues can concentrate in milk fat. Occasionally, milk from the recorder jar may accidentally be transferred to the bulk tank if the milker forgets a cow was treated. This is due to the normal human reaction to flick the switch and send the milk to the bulk tank. Leaky valves can also be a problem at the bottom of the jar, where some milk with residues leaks and contaminates the bulk supply.

It is important farmers clearly understand what off label and cascade treatment means and follow the correct withdrawal period. Withdrawal periods are shown on the medicine label and should be shown on the treatment SOP and updated by the practice if withdrawal periods change.

The statutory milk withdrawal period for off label or cascade treatment is a minimum of seven days – not seven days, but a minimum of seven days. The farmer must always test the milk to ensure it passes any residue test at the end of the minimum seven-day period before it can be sold. If the milk fails any residue test at day seven, it must then be discarded until it passes (Figure 4).

It is a legal obligation to discard all milk from treated cows until the end of the appropriate withdrawal period. The udder is highly vascular, with 500 litres of blood circulating around it for every litre of milk produced. Some farmers have been known to only discard milk from an individual quarter treated with an intramammary preparation. This can cause residue failures as these can pass from a treated to an untreated quarter.

Most farmers buy cows on trust and presume this milk is free from residues. It is possible cows may have been treated prior to purchase or may have calved early with milk still containing residues from dry cow therapy. Best practice is to assume milk from all purchased cows contains residues and withhold this from the bulk tank until residue screening tests confirm the milk has passed.

Dry cow therapy contains high levels of antibiotic that is contained in a slow release base and so can pose a significant risk of residue failures. The milk withdrawal period for some dry cow products can be as long as 58 days (54 days dry and 96 hours after calving) after treatment. Farmers should check medicine records every time a cow calves to make sure the milk withdrawal period has expired before returning her milk into the bulk tank.

Remember some dry cow products have a milk withdrawal period after calving. This is longer than the statutory 96 hours where milk needs to be withheld after calving. Farmers can get caught out here.

No need exists to test milk from individual cows at the end of the milk withdrawal period if a medicine has been administered following data sheet recommendations.

If a cow has been treated off label, or under the cascade, the milk must be tested before it can be sold. If any doubt arises about an individual animal, it is advisable to test before releasing the milk into the bulk tank. Some farmers might test cows with the intention to add their milk back into the bulk tank before the end of the milk withdrawal period. It is illegal to do this.

Dairy companies are taking a much tougher approach with residues. In the future it is likely most, if not all, will move to daily testing and penalties for failure will increase. It is important vets support their farmers to minimise risk and one of the best ways to do this is to encourage farmers to be MilkSure trained.

Some dairy companies already require all their producers to be MilkSure trained and go through an annual reassessment. It makes sense for someone from each veterinary practice to be suitably trained to deliver MilkSure training so it can be delivered to dairy clients. This is good for everyone, it will improve food safety and significantly reduce the number of bulk tank failures.