24 Mar 2020

Referral team uses CT images to design 3D-printed guides to enable precise placement of tiny 1mm diameter screws.

Ping after surgery, happy and on the road to a full recovery.

A vet team has given a tiny paralysed puppy the ability to walk again after using a 3D printer and a set of small screws to fix a life-threatening spinal cord defect.

Ping, a five-month-old male Chihuahua that weighs less than a bag of sugar, presented at Hamilton Specialist Referrals in High Wycombe after suddenly becoming paralysed.

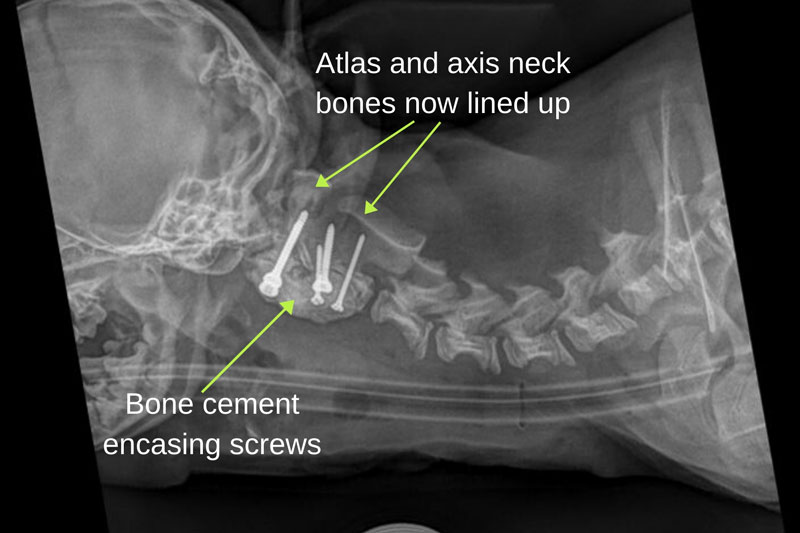

CT and MRI scans showed the bones in Ping’s neck had not formed correctly from birth, leading to atlantoaxial subluxation on the spinal cord in his neck.

Veterinary neurologist John Parker said: “The first two bones in the neck were partially dislocated. The second neck bone – the axis – hadn’t formed completely and the area needed stabilising to provide Ping any chance of recovery.

“However, Ping was so small – he weighed barely a kilogram – and in such a tiny space, traditional orthopaedic implants would be too large to place safely.”

The team at Hamilton worked with Vet3D, 3D printing specialists who used the practice’s CT images to design bespoke 3D-printed guides and enable precise placement of tiny 1mm diameter screws.

While waiting for the guides to be made, Ping was hospitalised in a neck brace.

Surgery took place six days later, with Mr Parker and surgery specialist Michael Hamilton stabilising the unstable region of Ping’s neck using the guided screws and encasing them in bone cement.

Ping made a remarkable recovery and one week later he was able to walk out of the hospital for a pain-free, happy, normal life.